Free Shipping Nationwide. 1-2 Day Delivery.

The Cutting Edge Science of Abrasives

The shape of a grain and how it fractures has a big effect on scratch pattern. That's why it's so important to pick the right grain type for what you want to do.

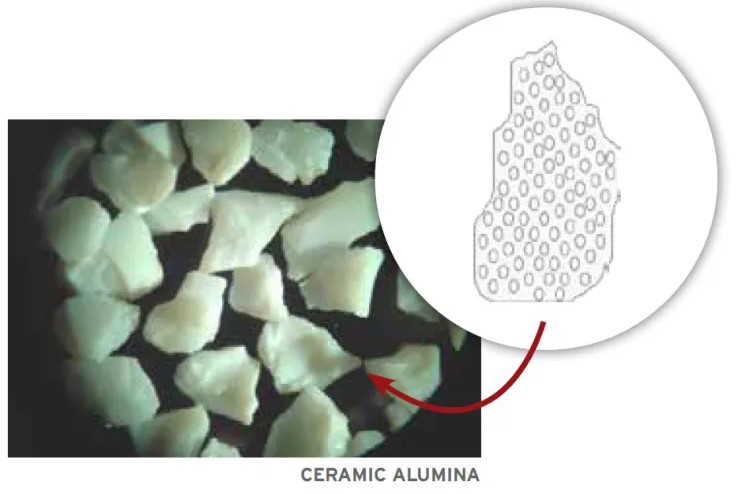

Ceramic

Ceramic alumina is engineered from sub-micron crystals of aluminum oxide. They're the sharpest and longest lasting of the grains. They are very consistent in shape and size.

Use for: sanding exotic woods, sanding off hard coatings like aluminum oxide finishes, and sport floors

Norton products: Red Heat, Blaze, Blaze Plus

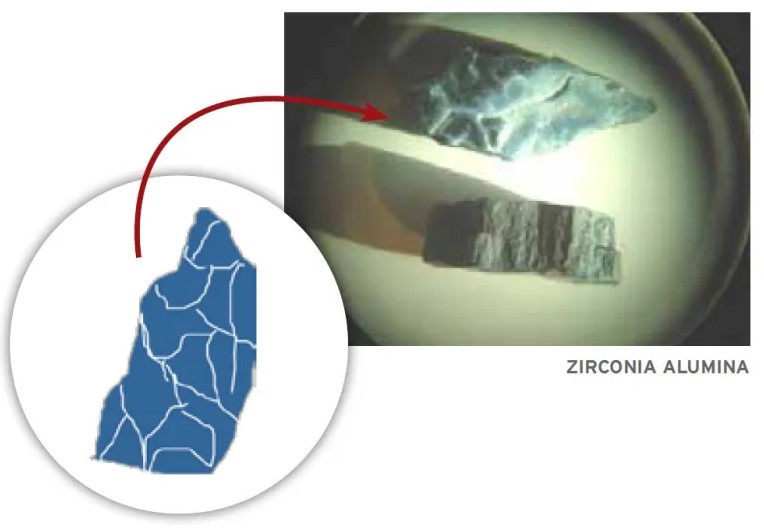

Zirconia

Zirconia alumina is a micro-fracturing grain, so it lasts longer than silicon carbide. It's engineered, so it's more consistent in size and scratch too.

Use for: sanding tougher coatings and harder woods

Norton products: Blue Fire

Silicon Carbide

Silicon carbide works great for sanding raw wood and removing old coatings. But it wears down quickly and can fracture inconsistently. It also sheds more during its initial use.

Use for: intial sanding passes, low grits

Norton products: Durite, Silicon Carbide

Aluminum Oxide

Aluminum oxide is a blocky grain that wears down quickly. However, it leaves a fine, consistent scratch pattern.

Use for: intercoat abrasion, low pressure finishing applications

Norton products: Sand Dollars

Upgraded screens: Mesh Power

Best Sellers:

Full Catalog: